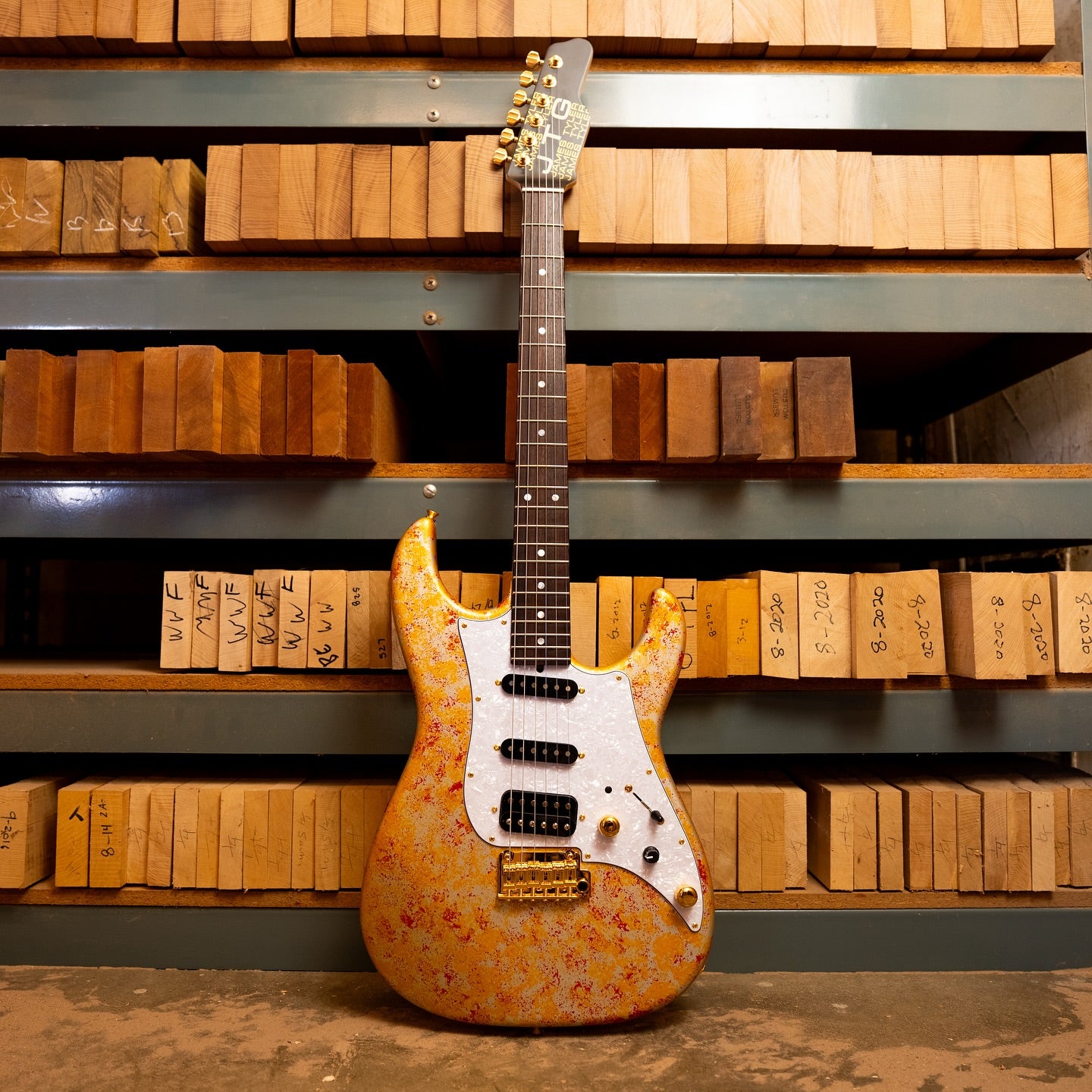

James Tyler Studio Elite Tequila Sunrise Shmear

This Elite Model isn’t just a guitar — it’s a statement. Built for serious players, collectors, and tone-chasers who know the difference.

Finish: James Tyler Studio Elite Tequila Sunrise Shmear

Neck: Quartersawn Maple, ultra-thin profile (.825” - .950”), compound Rosewood fretboard (10”-12” radius) Inlays: Rear Rout

Hardware:

Gold + Hipshot locking tuners Matching silver Logo tinted stainless steel frets

Electronics:

HSS configuration

Neck Pickup :James Tyler JTG 5500

Middle: JTG 5500

Bridge: James Tyler Super Shark

5-Way switching | Series/Parallel/Split | Lead/Rhythm circuit | Mid Boost

Body: Semi-hollow Mahogany master Tone

Pickguard/Backplate:

Black

Controls:

Gold knobs + Black buttons, black Midboost, rear-mounted 9V battery

Includes Hard Case

Available Upgrade Options:

• Body Wood: Swamp Ash – $256.41 AUD

• Body Wood: Mahogany – $217.95 AUD

• Body Wood: Mamywo (Jelutong) – $217.95 AUD

• Maple Top – $1,269.23 AUD

• Rear Rout – $0.00 AUD

• Hollow Body (any wood) – $384.62 AUD

• Neck: Mahogany – $141.03 AUD

• Neck: Roasted Maple – $153.85 AUD

• Neck: Birdseye Maple – $1,012.82 AUD

• Neck & FB: Birdseye Maple – $1,269.23 AUD

• Fingerboard: Ebony – $51.28 AUD

• Fingerboard: Brazilian Rosewood – $1,923.08 AUD

• Tuners: Non-Locking Hipshot – $0.00 AUD

• Pickguard Options: 3-Ply, Single-Layer, or Tortoise – $0.00 AUD

• Pickups: 2 Noise Cancelling Single Coils – $461.54 AUD

• Pickups: 3 Noise Cancelling Single Coils – $692.31 AUD

• Pickup: Super X Humbucker with Tap Button – $384.62 AUD

• Controls: Neck + Bridge Pickups On – $230.77 AUD

• Controls: Humbucker Split Button (High Output Only) – $230.77 AUD

• Controls: 3 Series/Parallel Buttons – $538.46 AUD

• Controls: 2 Series/Parallel Buttons – $358.97 AUD

• Controls: 3 Series/Split/Parallel Switches – $692.31 AUD

• Controls: 2 Series/Split/Parallel Switches – $461.54 AUD

• Controls: Push/Pull Pot – $243.59 AUD

• Bridge: Hipshot Hardtail – $0.00 AUD

• Bridge: Gotoh In-Tune 3-Saddle – $0.00 AUD

• Bridge: Floyd Locking Bridge and Nut – $487.18 AUD

• Hardware: Black – $371.79 AUD

• Hardware: Gold – $730.77 AUD

All upgrades subject to price and availability change with out notice based on USD.

Left Hand: Available to Custom Order

T&C: Pre Order (Approx ETA 13 Weeks). |. Image for Illustration Purposes Only

Read More